Description

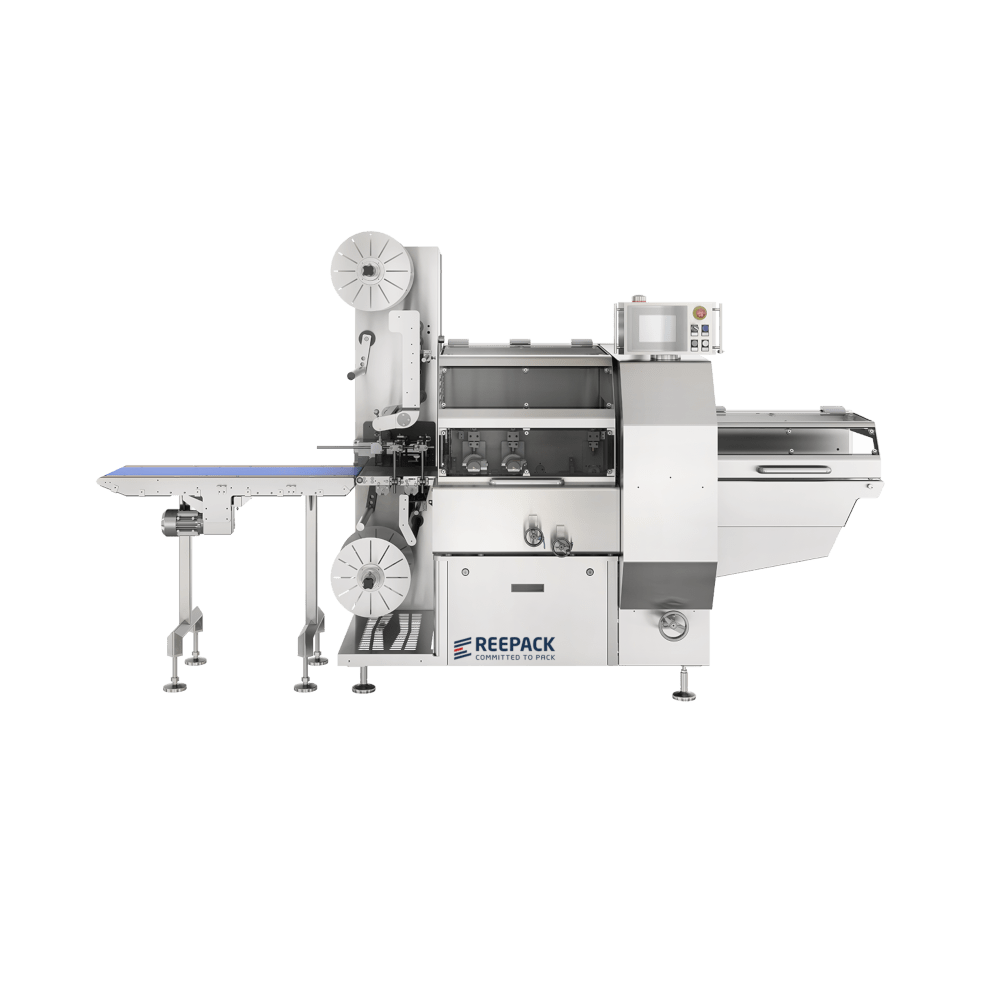

Result of a synergistic activity of R&D between Italy and Germany, Reepack’s ultimate flow-wrap machine ReeFlow 4S introduces an innovative packaging system. ReeFlow 4S presents a unique way to process different products and its four-sides sealing technology allow to achieve new levels of productivity revolutionizing the concept of fresh products packaged in Modified Atmosphere.

For Producer:

- Minimal use and waste of packaging materials

- High reduction of gas consumption (in MAP)

- Linkable with major automatic industrial slicers

- User-friendly settings to adjust packages sizes

- High production output (up to 200 pcs/min)

- MAP production output doubled

- Sliced products in one line

- Taking up little space

- Ideal for single portions

- Cost-efficient daily activity

- Rapid cleaning and maintenance

For Consumers:

- The ultimate packaging solution for ready-sliced food!

- Many different tastes at your convenience: Cured meats (e.g. salami, ham), Cheese, Meat, Fish, and more…

- Easy-opening cut

- Quick to use and dispose

- Healthy take-away solution

- Low-cost & eco-friendly packages

- Sustainable package-product ratio

Technical Specifications:

| Property | Value |

|---|---|

| Version | TB |

| Film reel mounting position | Top+Bottom |

| Longitudinal sealing position | Right+Left |

| Transversal Sealing system | Planet-gear motion |

| Type of packaging |  |

| Machine dimensions (mm)* | 3180 x 1460 x h1710 |

| Outfeed conveyor length* | 770 mm |

| Net Weight* | Apr. 1200 Kg |

| Power Supply* | 400V 3/N/PE 50/60 Hz |

| Power consumption* | Up to 20 kW |

| Compressed air* | 6 bar - 1 NL / c |

| Machine performance | Depending on product size |

| Film speed* | Up to 30m/min |

| Bag width* | Up to 300 mm |

| Bag lenght* | Up to 600 mm |

| Max. product height* | 25 mm |

| Sealing width* | Variable (longitudinal) |

| 15 mm (transversal) | |

| N° of seailing Jaws | 1 couple |

| Longitudinal Sealing rolls | 4 couples (all hot) |

| Film reel core diameter* | 76 mm |

| Film reel external diameter* | 350 mm |

| Max. film width | 350 mm |

| Human Interface | 9" colored touch-screen panel |

| Motors & Drives | 6-axis driven motors |

| OPTIONS | |

| Fixed/ Adjustable Folding Boxes | N/A |

| Printed Film Mark | Available on top, bottom or both |

| No Product no bag | Standard |

| Second heated couple of longitudinal sealing rolls | • |

| Additional jaws | Up to 3 couples total |

| Gas flushing system | • |

| Different sealing texture/width | • |

| Zig-Zag cut for easy-opening | • |

| Euro Hole - Circular Hole | • |

| Infeed belt conveyor | Different sizes and configurations upon request |

| Upper Belt | N/A |

| Film perforation system | • |

| Photocell for variable bag length | Standard |

| *Given data is reffered to standard machine configuration and may vary on a project basis | |