Description

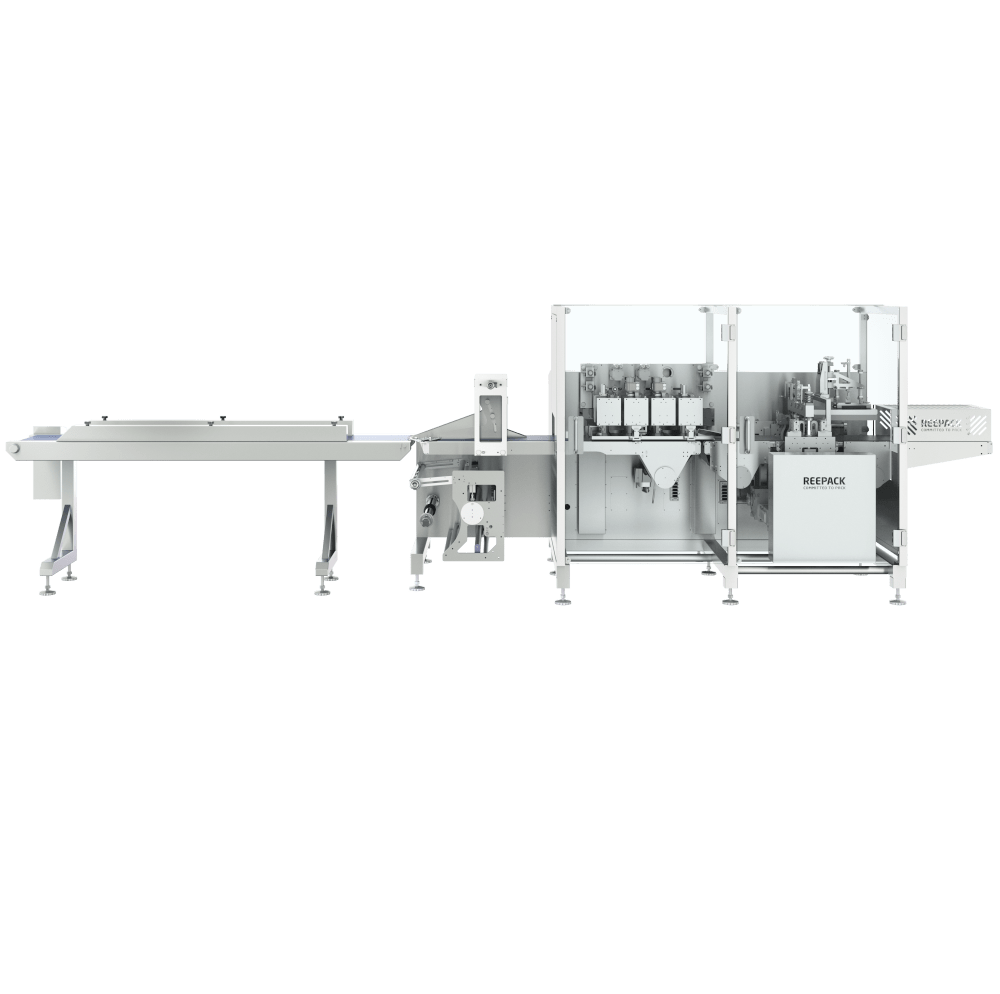

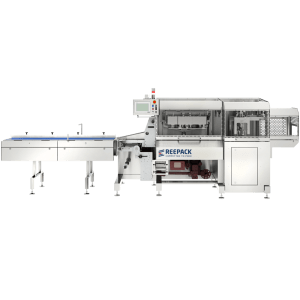

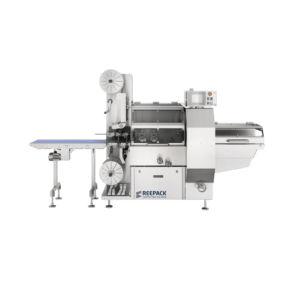

ReeFlow 300 is the Box Motion flow wrapper capable to pack Heavy & Larges pieces (Meat cuts, poultry, cheese) in pillow bag, flow bag, in shrink & MAP. This technology provides flexibility and guarantee quality hermetic seals, available with film reel holder unwinding from the top and bottom. The construction is fully in stainless steel and on a cantilevered frame, its high degree of protection combined with its design made to easily disassembled the parts for sanitisation, turn the Reeflow 300 machine into the ideal packaging machine for a very wide range of applications in the fresh food industry.

User friendly, designed to improve the operation and facilitate the work of the operator and maintenance, reduce the installation’s TCO (Total Cost of Ownership) and increase the return on your investment by lowering maintenance cost as well as optimizing changeover and sanitization time. Accurate and flexible, made to handle the widest variety of products and wrapping materials. The Programmable Logic Control (PLC) synchronise all the movements from the infeed conveyor, the film unwinding and the sealing devices.

Equipped with a large coloured touch-screen interface on lever arm, to set every single parameters and save up to 100 different personalized programs. The software is protected by four levels of access, each with a password. Manually loaded or integrated in a fully automatised packing line, the

Reepack Reeflow 300 machines provide the best class operational cost to our customers.

MAIN OPTIONS OPTIONAL PRINCIPALI

- Left hand version

- Flat belt infeed /Multibelt feeder

- Full automatic adjustments by reciepe

- Double reel holder with auto-splice

- Coding unit

- Misplace product

- Longitudinal sealing Re-fill and trimming

- Flow bag

- Gusetting device

- Deflating pressure pad

- Gas flush, Mix & analyser

- Quality control with reject

- ReeNext

TECHNICAL SPECIFICATIONS

| Property | Ree Flow 300 TW | Ree Flow 300 BW |

|---|---|---|

| Standard Infeed (Loading Area) | Lug conveyor (1.5 m) | Belt conveyor |

| NP-NB Function | Included | Included |

| Film Reel Holder | Top position | Bottom position |

| Max. Film Reel Width (opt.) | 800 (1000) mm | 800 (1000) mm |

| Max. Film Reel Diameter | 400 mm | 400 mm |

| Max. Film Reel Weigth | 40 kg | 40 kg |

| Sealing Rollers | Bottom position | Top position |

| Sealing Rollers Layout (opt.) | 3 pairs C-H-F (+1) | 3 pairs C-H-C (+1) |

| Sealing & Cutting Jaws | Box Motion System | Box Motion System |

| Vertical Movement of Sealing Jaws (opt.) | Pneumatic (Brushless) | Pneumatic (Brushless) |

| Sealing Jaws' Lenght (opt.) | 350 (250/400) mm | 350 (250/400) mm |

| Max. Product Height | 200 mm | 200 mm |

| Standard Outfeed (Length) | Belt conveyor (900 mm) | Belt conveyor (900 mm) |

| Max. Film Speed*1 | 60 m/min. | 60 m/min. |

| Max. Packaging Output Full Servo)*1 | 80 PPM (100 PPM) | 80 PPM (100 PPM) |

| Standard Motorization | 4-axis Brushless (+5) | 5-axis Brushless (+5) |

| Control HMI | Schneider 10'' Touch-screen | Schneider 10'' Touch-screen |

| Software | Reepack | Reepack |

| Standard Power Supply (opt.) | 400V 3/N/PE 50/60 Hz. (230V 3/PE 60Hz. & others) | 400V 3/N/PE 50/60 Hz. (230V 3/PE 60Hz. & others) |

| *1 Depending on film and product characteristics | ||