Description

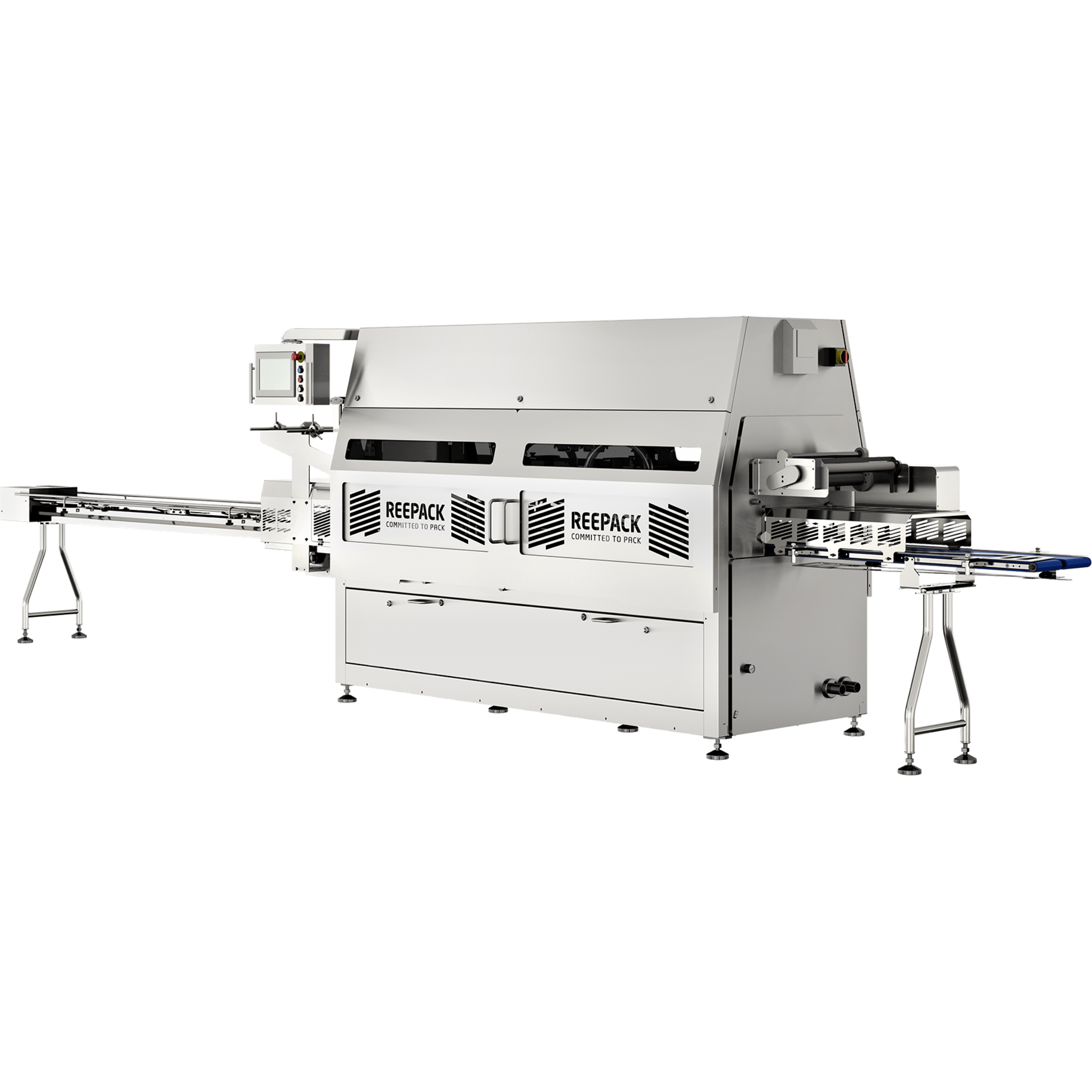

ReeMaster is based on a new die set concept which accomplishes uncommon closing force allows the processing of all the packaging materials PP, PE, C-PET, A-PET, EPP, EPET etc.,reaches a new level of productivity. Equipped with TPS system for the tray positioning (Reepack patent) and an automatic discharge double belts with differenced speeds allowing the exit of one line at the time (2 to 1 conveying conveyor) providing a continuous product flow. ReeMaster is able to exploit all the peripheral devices used in the food packaging market such as denesters, dosing units, printers, etc. ReeMaster takes the same film movement advantages we have optimized in years of use with the ReeClose models (we manage 90° film movement looking to the tray flow direction allowing a reduction of index and a longer reel life); in addition to these advantages a stand alone film trolley combined with and an automatic film mounting realize an easy & fast film exchange operation avoiding any accesses inside the machine.

[table “61” not found /]